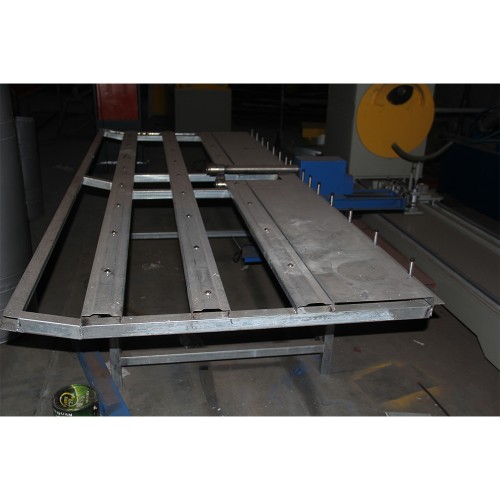

Non-pressurized solar tank production line

Non-pressurized solar machinery

1. Sheet Cutting (A or B)

A. QJ11-1300 Motor-driven Shearing Machine

Application: putting and cutting for sheet

| Parameter | Value |

|---|---|

| Material Max. Width | French Schneider |

| Max. Thickness | L12000 x W3800 x H3500mm |

| Labor | L3550xW3800xH3500mm |

| Max. Width of Sheet on Rack | |

| Max. Weight of Sheet on Rack | L6000, x W2600 x H2100mm |

| Voltage | Hot dipped galvanized steel, Stainless steel 304 |

| Power | Centrifugal Pump 150L/min 7.5kW = 10HP |

| Max. Efficiency in 8 Hours | 20~30Bar, 130L/min adjustable |

| Machine Weight | 7.5kw x 2 = 10HP x 2 |

| Size (L*W) | 4000mm*1600mm |

B. KP-Z All-automatic CNC Kaiping Line

Application: putting and cutting for sheet

Deployment Component:Steel coil putting stand 2sets,Tractor 1set,Hydraulic system 1set,Control cabinet 1set.

| Parameter | Value |

|---|---|

| Length Positioning Accuracy | ±1.0mm |

| Material Max. Width | 13000mm |

| Max. Thickness | 2mm galvanized steel sheet |

| PN | 400KN |

| Air Pressure | 0.5-0.8Mpa |

| Total Power | 13KW |

| Voltage | 380V 50HZ |

| Labor | 2 people |

| Max. Efficiency in 8 Hours | 5000 pcs |

| Total Weight | 3200kg |

| Size (L*W) | 8600mm*2400mm(2 rolls of sheet) Note: each additional sheet roles increased in length 1200mm, width is constant |

2. Inner Tank and Outer Tank Punching Machine (A or B)

A. PF2000-25RS Double Station CNC Punching Machine

Application: All-automatic Punching and Flanging for sheet

| Parameter | Value |

|---|---|

| Mould | 2 |

| Positioning Accuracy | ±0.10mm |

| Sheet Max. Width | 1250mm |

| Sheet Max. Thickness | 2mm galvanized steel sheet |

| Sheet Max. Length | Unlimited |

| PN | 250KN |

| Air Pressure | 0.5-0.8Mpa |

| Total Power | 6 KW |

| Voltage | 380V 50HZ |

| Labor | 1 people |

| Max. Efficiency in 8 Hours | 12000 holes |

| Total Weight | 6000kg |

| Size (L*W) | 2500mm*4000mm |

| Drawing Input Format | DXF formator or Program |

B. PF9025—12G-B All-automatic CNC Turret Punching Machine

Application: All-automatic Punching and Flanging for sheet

| Parameter | Value |

|---|---|

| Mould | 12 |

| Positioning Accuracy | ±0.10mm |

| Sheet Max. Width | 1250mm |

| Sheet Max. Length | Unlimited |

| PN | 250KN |

| Sheet Max. Thickness | 2mm galvanized steel sheet |

| Air Pressure | 0.5-0.8Mpa |

| Labor | 1 people |

| Total Power | 12KW |

| Voltage | 380V 50HZ |

| Total Weight | 11000kg |

| Size (L*W) | 5000mm*120000mm |

| Drawing Input Format | DXF formator or Program |

3. Punching Mould

12kg/set

4. HF-Z All-automatic TIG Welding Machine

Application: inlet and outlet nut welding

| Parameter | Value |

|---|---|

| Nut Size | ½— 1½ |

| Material Max. Thickness | 2.0mm |

| Max. Output Power | 12KW |

| Power | 0.1KW |

| Voltage | 220V 50HZ |

| Argon Arc Welding Machine Voltage | 380V |

| Air Pressure | 0.5-0.8Mpa |

5. F100-1800 Straight Welding Machine

Application: straight welding for inner tank

| Parameter | Value |

|---|---|

| Max. Welding Thickness | 0.5mm+0.5mm stainless steel |

| Max. Welding Length | 3600mm |

| Main Transformer Rated Capacity | 100KVA |

| Voltage | 380V 50HZ |

| Max. SCC | 20KA |

| Duty Circle | 20% |

| Air Pressure | 0.5-0.8Mpa |

| Labor | 1 people |

| Max. Efficiency in 8 Hours | 100 pcs |

| Weight | 450kg |

| Size (L*W*H) | 2500mm*550mm*1700mm |

6. Inner Tank Grooving Machine (A or B)

A. QJ-3000 Air-Pressure Type All-automatic Grooving Machine

Application: grooving for inner tank

| Parameter | Value |

|---|---|

| Effective Length of Equipment | 3000mm |

| Wheel Number | 12 sets |

| Sheet Max. Thickness | 0.5mm |

| Power | 1.5KW |

| Voltage | 380V 50HZ |

| Air Pressure | 0.5-0.8Mpa |

| Max. Efficiency in 8 Hours | 360 pcs |

| Labor | 1 people |

| Weight | 1250kg |

| Size (L*W*H) | 4400mm*800mm*1800mm |

B. QJ-1800 All-automatic Grooving Machine

Application: grooving for inner tank

| Parameter | Value |

|---|---|

| Effective Length of Equipment | 1800mm |

| Wheel Number | 6 sets |

| Sheet Max. Thickness | 0.5mm |

| Power | 1.5KW |

| Voltage | 380V 50HZ |

| Air Pressure | 0.5-0.8Mpa |

| Labor | 1 people |

| Max. Efficiency in 8 Hours | 150 pcs |

| Weight | 500kg |

| Size (L*W*H) | 4400mm*800mm*1800mm |

7. LZ-Z×3000 Double-side All-Automatic Lathe Machine

Application: flanging for inner tank

| Parameter | Value |

|---|---|

| Effective Length of Equipment | 3000mm |

| Mould Diameter | Ø360 Ø380 |

| Max. Flanging Thickness | 0.5mm |

| Power | 2.0KW |

| Voltage | 380V 50HZ |

| Air Pressure | 0.5-0.8Mpa |

| Labor | 1 people |

Haining Boyi New Material Co., Ltd. | Solar Water Heater & Accessories Manufacturer

+86-18857388282| moc.lairetam-iyob@ofni